Home > News

Home > News

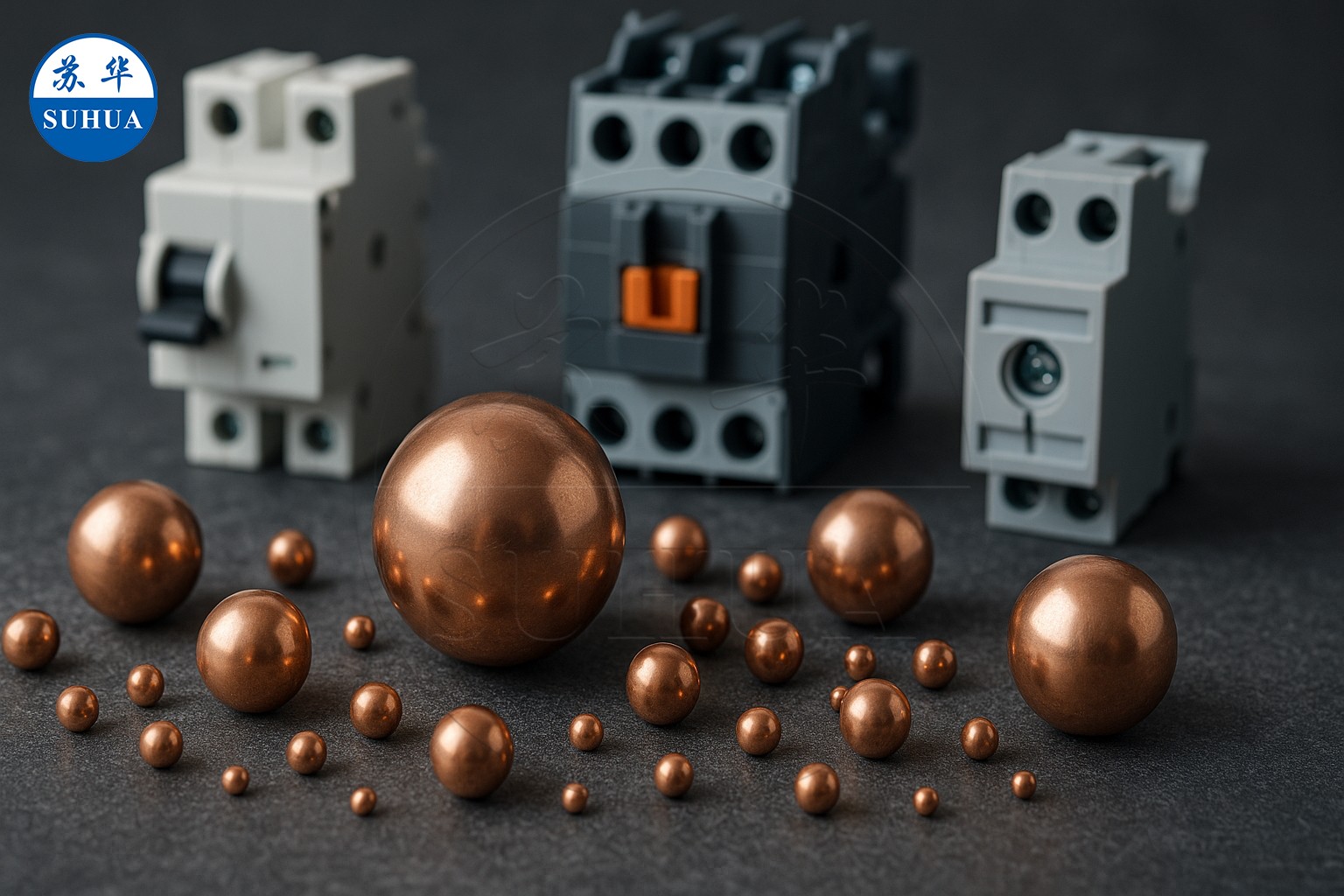

In the field of low-voltage electrical devices, copper balls play a critical role as precision metal components. They are essential not only for conduction, positioning, and motion control but also for ensuring stable operation thanks to their excellent electrical conductivity, corrosion resistance, and workability.

Copper has one of the highest electrical conductivities among common metals, second only to silver, with a conductivity rating of up to 97% IACS (International Annealed Copper Standard). In low-voltage electrical equipment, copper balls are widely used in contact mechanisms such as push-button switches, circuit breakers, and relays. They ensure instant and stable current transmission, minimize contact resistance, and enhance both response speed and operational safety.

Low-voltage devices often operate in humid, dusty, or mildly corrosive environments. Copper balls offer strong oxidation resistance, maintaining their electrical performance over long-term use without rusting or failing. Furthermore, precisely machined and polished copper balls have an optimal surface hardness that minimizes wear and extends the service life of the device.

In certain mechanical structures of low-voltage electrical devices, copper balls are used for positioning, support, and transmission. In rotary control switches and automatic reset buttons, for instance, copper balls ensure smooth movement and accurate positioning, preventing malfunction due to excessive friction or misalignment.

Low-voltage electrical applications demand strict specifications for copper balls, including diameter, tolerance, surface finish, and hardness. As a B2B manufacturer and trader, we can produce copper balls ranging from 0.5mm to 50mm in diameter, with precision grades from G10 to G100. We control surface smoothness and other parameters to meet the unique requirements of different electrical equipment manufacturers.

Conclusion

Although small in size, copper balls are an “invisible hero” in the reliable performance of low-voltage electrical devices. High-quality copper balls not only enhance product performance but also reduce maintenance frequency and failure rates. Choosing the right copper ball supplier directly impacts the stability and market competitiveness of your product.

As a professional B2B manufacturer and supplier of precision balls, we offer consistent quality and responsive customization services to help your products stand out in a competitive market.

View More(Total0)Comment Lists